- Tel :+91 7400344448

- Email Us :danish@kraftsmengroup.com

We are KRAFTSMEN, dedicated to providing high-tech solutions in manufacturing, factory automation, product design and in the creation of special purpose machinery. Since its foundation in Mumbai, in India, Kraftsmen has focused on the development of solutions that add speed, precision and flexibility to the processes.

We pride ourselves from our experience, have delivered successful applications and have become a trusted supplier to many companies that have looked for alternative automation suppliers,

matching the perfect balance between price and quality. Our machines are aesthetically designed keeping customers need in mind and with stress on quality workmanship and productivity.

With the support of strong infrastructure facilities, we have highly competent and innovative design department operating with the latest design software like, SolidWorks for mechanical design, PC-Schematic for electrical design. We possess state-of-the art production capacity, which is backed by hi-tech machines and latest technology.

Have a chat with us to see how Kraftsmen can help automate your processes. An initial meeting will give our customers the chance to bounce ideas off our engineers to determine the best course for automation in their business.

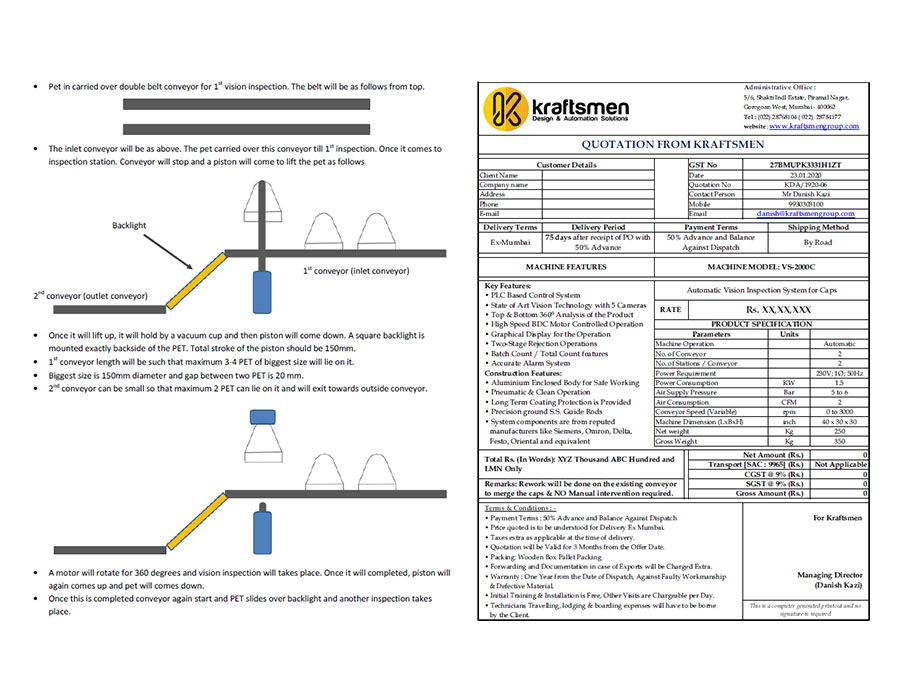

After the initial meeting, a specification is typically supplied by our customers detailing their requirements. At this stage, our engineers will think up a concept and provide a quotation for your consideration.

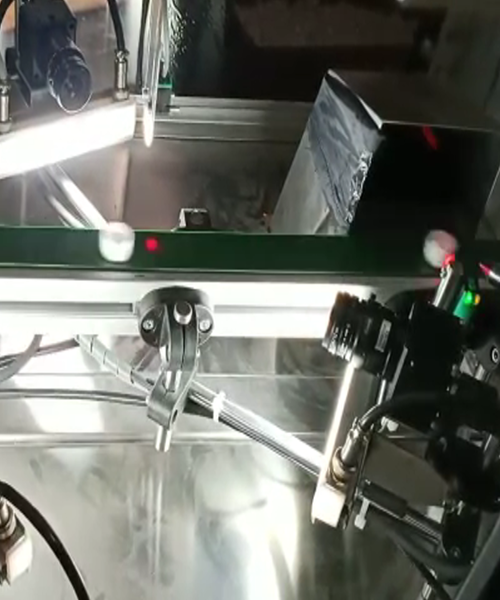

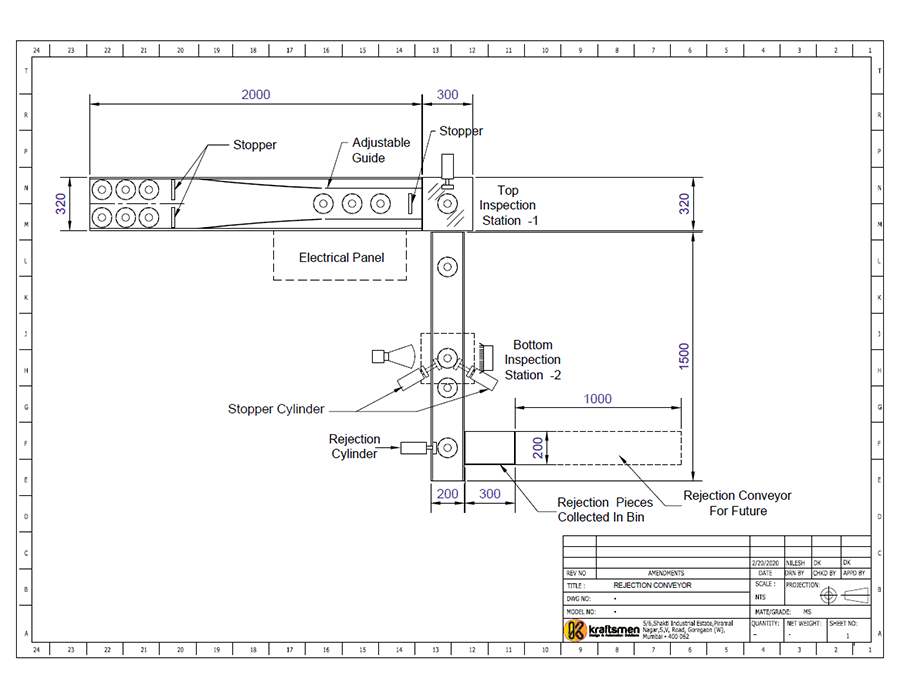

This stage is where all the engineering disciplines work together to visualize and flesh out concepts, using 3D CAD and simulation software. Our state-of-the-art manufacturing facility also allows us to produce rapid prototypes to prove concepts and ensure that the final design is successful.

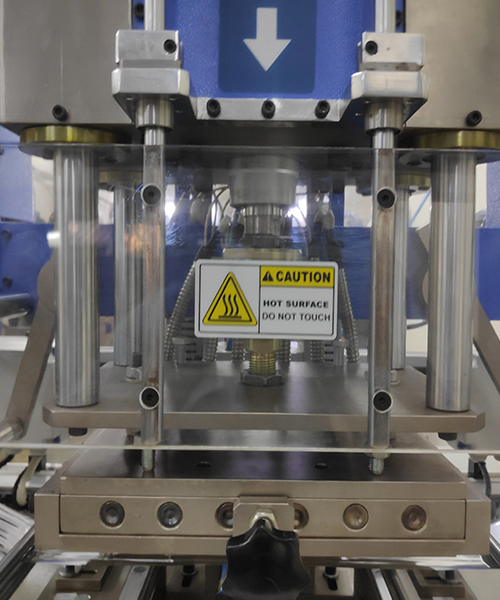

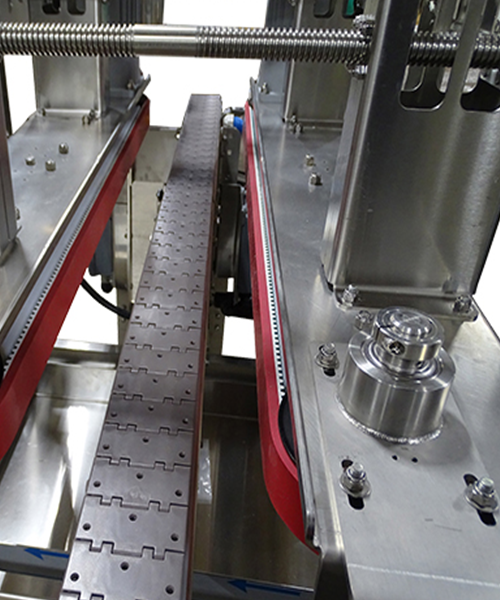

Once the design is completed, our team of expert and experienced machinist and fitters ensure that designs are realized to specified tolerances and quality finishes. Furthermore, having in-house manufacturing facilities mean that we control every part of the manufacturing process, which in turn, mean that all our products are made to the utmost quality that Kraftsmen is known for.

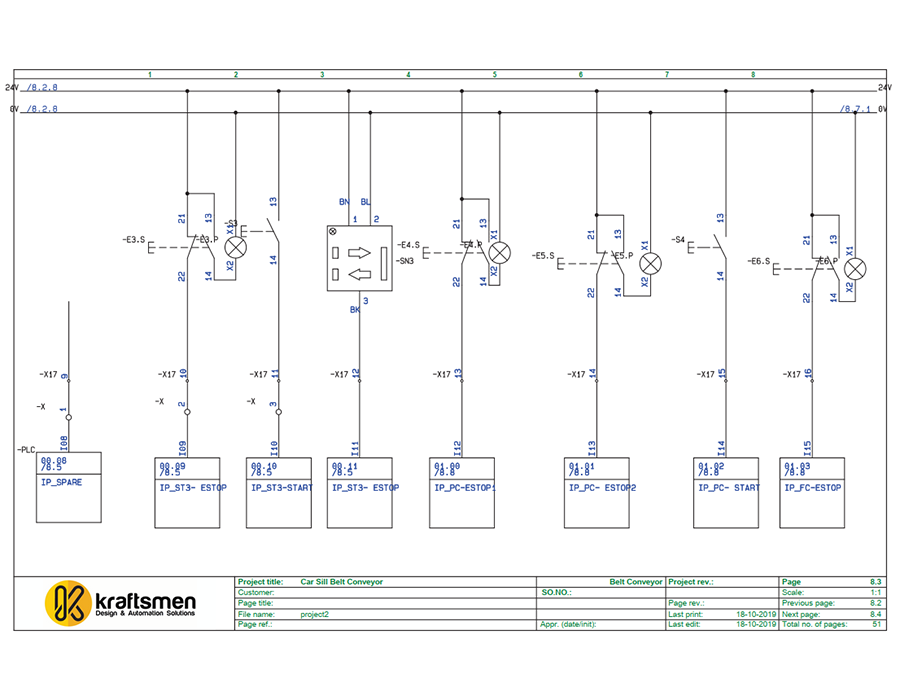

Working in tandem, our electrical engineers design electrical cabinets to suit the cell design requirements to required safety levels. Our programmers also start mapping and laying out foundation program parameters so that when the machine is finally built, they can start the programming process straight away.

The project is only really completed once the design has been tested to the customer's requirements. Prior to shipping to the customer's site, in most cases we can setup the entire production cell/machine on our factory floor to ensure that any issues that may have been overlooked can be spotted and rectified.

The same crew who installed and tested the production cell/machine will facilitate the on-site installation and commissioning. This step will include final touch-ups and tune-ups and a Site Acceptance Test (SAT).

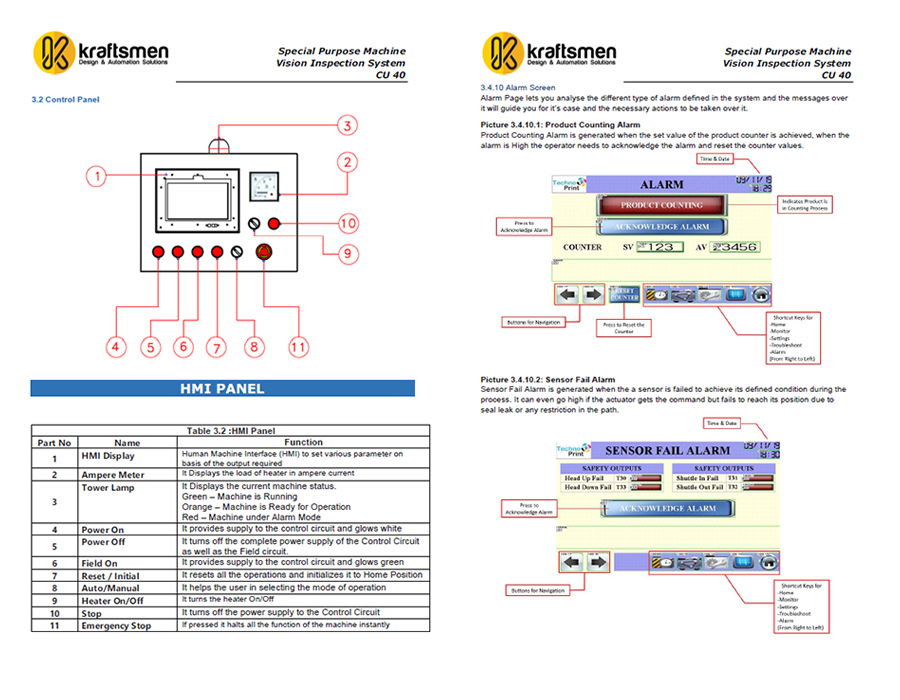

Our machines typically include an Operator's Manual, which will outline recommended operating procedures and troubleshooting guides. In conjunction with an Operator's Manual, we also provide comprehensive training to operators to ensure that they know how to operate the machine, and also how to overcome potential issues

We recognise that you need efficient, cost-effective and reliable machines & solutions to meet the constantly-changing challenges in your markets.

We devote all our energy into addressing the challenges you face and with a dedicated team we can support and advise you at all stages.

We have a highly motivated team of engineers, designers, tool makers and machinists, who contribute their skills to achieve the best possible outcome for our customers. Utilising state of the art equipment and software, we aim to achieve the most technically sound solution possible.

Our organization aims at absolute customer satisfaction with a strong focus on reliable & quality products.

Instant technical support for all requests.

We offer you a complete solutions for your production process.

We are offering solutions for different types and applications of products.